Best Manufacturing Software

List of the best manufacturing software for your business are Oracle NetSuite ERP, Infor LN, CREST ERP, CONNETINBOT, and MobileERP. Manufacturing management software automates materials planning, production tracking and scheduling, and product lifecycle management.

No Cost Personal Advisor

List of 20 Best Manufacturing Software

#1 Cloud ERP for Fast-Growing Businesses

NetSuite, #1 cloud ERP, is an all-in-one cloud business management solution that helps more than 29,000 organizations operate more effectively by automating core processes and providing real-time visibility into operational and financial performance. Read Oracle NetSuite ERP Reviews

Explore various Oracle NetSuite ERP features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

- Time & Attendance Management

- Case Management

- Expense Tracking

- General Ledger

- Manufacturing

- Recurring invoice

- CRM

- Accounts Receivable

Oracle NetSuite ERP Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Inventory, Order Management & Manufacturing Softwa

SOS Inventory provides cloud-based, end-to-end solutions for small to medium businesses. No start-up costs and very affordably priced while boasting a full suite of features found in high-end ERP solutions. Read SOS Inventory Reviews

Explore various SOS Inventory features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all SOS Inventory Features- Production Management

- Mobile Access

- Invoicing

- Payment Processing

- Barcoding / RFID

- Inventory Tracking

- Retail Inventory Management

- Kitting

Pricing

SOS Inventory Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Category Champions | 2024

#1 Cloud ERP for Fast-Growing Businesses

NetSuite, #1 cloud ERP, is an all-in-one cloud business management solution that helps more than 29,000 organizations operate more effectively by automating core processes and providing real-time visibility into operational and financial performance. Read Oracle NetSuite ERP Reviews

Explore various Oracle NetSuite ERP features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

- Contact Import/Export

- Sales Order

- Cross Docking

- Multi-Store Management

- Revenue Recognition

- Content Management

- Time & Attendance Management

- Mailing list management

Oracle NetSuite ERP Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Emergents | 2024

Efficiently executing the complex processes

Infor M3™ is a powerful cloud enterprise resource planning (ERP) solution using the latest technologies to establish a foundation for digital transformation. M3 provides powerful analytics in a multi-company, multi-country and multi-site with exceptional user experience to deliver faster time to value and proven outcomes for customers. Learn more about Infor M3

Explore various Infor M3 features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all Infor M3 Features- Premium Support & Training

- Checkout

- Import / Export Management

- Relationship Intelligence Agent

- Polls / Voting

- Costing

- Customer Enquiry Widget

- Analytics/ROI Tracking

Infor M3 Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Category Champions | 2024

A Businessman's Best Friend

Vyapar is a GST-compatible invoicing and accounting solution for small businesses. You can use it to create GST bills, fulfill orders, generate GSTR reports, track payments/expenses, and manage your inventory. Besides, you can use it to customize invoices and collect payments online. Read Vyapar Reviews

Explore various Vyapar features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all Vyapar Features- Retail Inventory Management

- Report Export

- Financial Accounting

- Transaction History

- Purchase Order

- Custom Fields

- Remote Order Entry

- Data Import & Export

Pricing

Silver- Desktop (1 year)

$ 40

Device/Year

Silver- Desktop + Mobile (1 year)

$ 47

Device/Year

Silver- Desktop (3 years)

$ 92

Device/ 3 Years

Vyapar Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Contenders | 2024

Software by MobileERP Softech P Ltd

MobileERP365 Software – This is FREE ERP on Cloud with chargeable services. Yes unbelievable, but yes this is true. With CloudERP your are not going to spend on ERP Software. ERP Software which other companies spend THOUSANDS of dollars comes free for you. This is in depth ERP Comparable to features of big BRAND ERP giants. Read MobileERP Reviews

Explore various MobileERP features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all MobileERP Features- CRM

- Purchase Order

- Manufacturing

- Invoicing

- Financial Accounting

- Applicant tracking

- HR & Payroll

- Inventory Management

MobileERP Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Category Champions | 2024

The Complete Business Management Software for SMEs

An integrated bussing accounting and management solution, BUSY is a one-stop solution for your financial and payroll needs. It offers multi-location inventory, multi-currency support, order processing capabilities, and helps you make informed decisions. Moreover, it is best suited for the FMCG, retail, manufacturing, trading, and distribution businesses. Read Busy Accounting Reviews

Explore various Busy Accounting features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Pricing

Basic version

$ 100

Per Year

Standard version

$ 188

Per Year

Enterprise version

$ 275

Per Year

Busy Accounting Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

High Performer | 2024

A Unique Solution for every Unique Business

MMI XPERT is a Complete solution for small and midsize retailers, wholesaler and Manufactures operating everything from a single store to a whole chain. It is comprehensive and scalable for those business focusing on significant growth. Read MMI Xpert - ERP Reviews

Explore various MMI Xpert - ERP features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all MMI Xpert - ERP Features- Fund accounting

- Manufacturing

- Business process modeling (BPM)

- HR & Payroll

- Employee Data Base

- Sales and Distribution

- General Ledger

- Supplier and Purchase Order Management

MMI Xpert - ERP Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Contenders | 2024

Software by VISW Consultancy Services

Being a software development company and ERP solution provider, we have got specialization in diverse software solutions with competence in e-marketing. Read Visw Production Management Reviews

Explore various Visw Production Management features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Visw Production Management Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Category Champions | 2024

Power of Simplicity

TallyPrime is India’s leading business management software for GST, accounting, inventory, banking, and payroll. TallyPrime is affordable and is one of the most popular business management software, used by nearly 20 lakh businesses worldwide. Read TallyPrime Reviews

Explore various TallyPrime features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all TallyPrime Features- Fund accounting

- Loan & Advances Management

- Multi-Branch Connectivity

- Multi Currency

- Web Access / Restoration

- Banking Integration

- Account Management

- Cash Management

TallyPrime Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Category Champions | 2024

orion-erp

ORION Enterprise is a dynamic enterprise resource planning solution that allows organizations to smoothly integrate disparate teams, functions, processes, and systems. 3i Infotech is a global Information Technology company committed to Empowering Business Transformation. Read ORION ERP Reviews

Explore various ORION ERP features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all ORION ERP Features- Stock Taking

- Employee Lifecycle Management

- Product Management

- Receipt Management

- Transport / Fleet management

- Multi Smart Device (Desktop/ Laptop/Notepad/Mobile)

- Configuration Management

- Import/Export Management

ORION ERP Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

High Performer | 2024

GST Billing software with Inventory & Accounts

Simple Billing software with complete inventory and accounts modules. It's fast, reliable and easy to maintain. Ideal for businesses that have a large number of invoices and deals in 100's of SKU's. Typically used by distributors, retailers and small manufacturers. Read Horizon ERP Reviews

Explore various Horizon ERP features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all Horizon ERP Features- Multiuser Login & Role-based access control

- Monthly GST Report

- Multi Company

- Account Tracking

- Order Management

- User Roles

- Purchasing

- POS invoicing

Pricing

SINGLE PC License

$ 192

One Time

THREE PC License

$ 384

One Time

EIGHT PC License

$ 746

One Time

Horizon ERP Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Contenders | 2024

We can make IT possible

Banibro is one of the leading providers of ERP solutions and holds expertise in developing mobile and web applications as well. We offer personalized solutions that streamline and increase your online presence. Read Banibro ERP Reviews

Explore various Banibro ERP features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all Banibro ERP Features- Multi-Country

- CRM

- Budgeting & Forecasting

- Employee Lifecycle Management

- Analytics & Reporting

- HR Management

- Data Protection

- Logistics

Banibro ERP Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Emergents | 2024

Software by Datascan Information Systems

Datascan Information systems is a Pune, India based integrated software solutions provider specializing in the field of customized Enterprise Resource Planning (ERP) software for small to medium scale manufacturing (SMEs) and trading companies. Learn more about ClarityERP

Explore various ClarityERP features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all ClarityERP Features- Payroll

- Accounting

- Billing & Invoicing

- Material Management

- Enterprise Asset Management

- ERP

ClarityERP Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Category Champions | 2024

Most Affordable ERP Software

It is the best ERP solution designed to grow seamlessly with your business. CREST will accommodate additional business process and functionalities as your business scale over time. CREST is a fully integrated ERP product. Read CREST ERP Reviews

Explore various CREST ERP features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all CREST ERP Features- Business intelligence (BI)

- Audit Trail Logs

- 3rd Party Integrations

- Project Management

- Human Resources Management System

- Jobwork/Insourcing Management System

- Distribution Management

- Purchase Order

CREST ERP Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Contenders | 2024

SAP Business One Implementation & Support

Uneecops SAP Business One is a cost effective, integrated ERP software for SMEs. Made specifically to meet the demands of small and medium businesses, Uneecops helps you manage your business as per set international standards. Covers all key functions like productions, inventory, finance, sales, HR and more. Read Uneecops SAP Business Reviews

Explore various Uneecops SAP Business features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

- Purchase Order

- Integration capabilities

- Business process modeling (BPM)

- Dispatching

- HR & Payroll

- Inventory Management

- Sales and Distribution

- Supplier and Purchase Order Management

Uneecops SAP Business Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Emergents | 2024

Process Manufacturing ERP Software

BatchMaster ERP is a complete ERP tool explicitly built for formula/recipe-based manufacturers to help them streamline manufacturing, distribution, quality, regulatory compliance, and financial reports while also integrating with your existing financials/accounting software. Read BatchMaster ERP Reviews

Explore various BatchMaster ERP features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all BatchMaster ERP Features- Accounting Management

- Nutrition Analysis

- Sales Management

- Sales History

- Formula Costing

- Production Management

- Formula Management

- Inventory Management

BatchMaster ERP Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Contenders | 2024

Accelerate | Innovate | Compete

An all-in-one cloud ERP that provides real-time visibility and automation of fundamental company operations for operational excellence. AI and machine-learning-driven statistics, predictive analytics, and forecasting are all available. Read Focus ERP Reviews

Explore various Focus ERP features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all Focus ERP Features- Audit Trail Logs

- Credit card processing interface

- Multiple Data Sources

- Category Customization

- Internal Chat Integration

- Usability Testing

- Textile Pattern Design

- Payment Processing

Focus ERP Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Contenders | 2024

Simplifying and automating discrete manufacturing

Infor LN™ is a cloud enterprise resource planning system serving the needs of discrete manufacturers around the world providing the visibility they need to quickly respond to customer, supplier, and regulatory needs—with no software customizations required. Read Infor LN Reviews

Explore various Infor LN features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all Infor LN Features- Productivity To-go

- Process Ink Calculation

- Logistics

- Production Scheduling

- Asset Planning

- Traceback & Traceforward

- Prototyping

- Customer Service History

Infor LN Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

Emergents | 2024

Software by CBO ERP Limited

CBO is a best, cost effective and flexible Pharma SFA for pharmaceutical companies. Software is capable of importing and exporting existing data from all the other billing and inventory software and can also be integrated with in TALLY. Read CBO Reviews

Explore various CBO features, compare the pricing plans, and unlock the potential of seamless operations by selecting the right software for your business.

Features

View all CBO Features- Contact Management

- Inventory Management

- Mobile App

- Workflow Automation

- Stock Management

- MIS Reports

- Sample & Gift Inventory

- MR Information

CBO Caters to

- StartUps

- SMBs

- Agencies

- Enterprises

In the current times, manufacturing software is a critical tool in modern industrial and manufacturing operations. It plays a pivotal role in streamlining and optimizing various aspects of the production process. It encompasses a diverse range of computer programs and applications designed to facilitate, manage, and enhance manufacturing processes.

The manufacturing software category has evolved significantly over the years, aligning itself with technological advancements to meet the ever-changing demands of the manufacturing industry. Let’s dive into this guide to learn more.

What is Manufacturing Software?

Manufacturing software refers to a specialized category of computer programs designed to streamline and optimize various aspects of the manufacturing process within a company or organization.

It is a vital component that helps in planning, supervising, and managing the manufacturing process from raw materials to finished goods with the ultimate goal of boosting productivity, cutting costs, and enhancing efficiency. Software designed specifically for the manufacturing sector includes a variety of features and functions.

Who Uses Manufacturing Software?

Manufacturing software is utilized by various professionals and roles within a manufacturing organization to enhance efficiency and productivity. The key users of manufacturing software include:

-

Production Managers

Production managers play a pivotal role in overseeing the day-to-day operations on the manufacturing floor. They depend on manufacturing software to create production schedules, allocate resources, and monitor real-time progress. This software aids in optimizing workflow, assigning tasks to employees, and guaranteeing the achievement of production goals with the highest degree of efficiency.

-

Quality Control Managers

Quality control managers play a pivotal role in upholding the quality and uniformity of manufactured goods. They make use of manufacturing software to institute quality control procedures, establish quality benchmarks, and monitor instances of product defects or deviations from specified standards. This software aids them in detecting and addressing issues at the early stages of the production process, thereby reducing waste and ensuring adherence to industry regulations and standards.

-

Inventory Managers

Inventory managers are entrusted with the critical duty of maintaining optimal levels of raw materials, work-in-progress items, and finished goods. Manufacturing software plays a vital role in supporting them in overseeing inventory by providing real-time visibility into inventory levels, forecasting demand, and closely tracking inventory movements. This empowers them to proactively prevent stockouts, minimize excess inventory, and refine procurement processes, ultimately leading to cost-effectiveness and the prudent allocation of resources.

Why Should Companies Have Manufacturing Software?

Manufacturing software is an integrated application system that handles all critical functions for manufacturing organizations. It manages all processes for manufacturing companies in a flexible and agile manner. Manufacturing management software is a holistic solution from sourcing and raw materials to inventory management, quality control, and capital budgeting.

Specialized software for free manufacturing software for small businesses in India can help them become more responsive and gain a definite competitive advantage. It is wise for firms to invest in manufacturing process software to increase efficiency and business revenues quickly.

Top Manufacturing Software Vendors by Company Size

|

Enterprise |

Medium |

Small Business |

|---|---|---|

| Oracle Netsuite | Infor CloudSuite | |

| Focus MRP | FishBowl | |

|

- |

Odoo | IQMS |

Dedicated manufacturing software will ensure that you can track and control the manufacturing process steps to give you better clarity to run your business smoothly. The software will centralize the workflow, like material requirements, production planning, project management, and tracking the cost for each step. The right software will help you plan and run your operations efficiently by streamlining processes and giving you an advantage over others.

Here we will understand the leading manufacturing software providers and how they can greatly help businesses.

Enterprise-Grade Manufacturing Software

Enterprise-grade free manufacturing software for small businesses in India will include all the departments’ functions and procedures in one software. It is suitable for large-scale manufacturing as it will consist of the end-to-end details to manage your entire manufacturing production software. Selecting the right software for your business will take time and patience, but the seamless integration and ease of using it will be worth your effort.

Some of the leading manufacturing software providers are Infor M3 and IFS.

|

|

|

|---|---|---|

|

Infor M3 |

IFS |

|

| Free Trial |

Not Specified |

Not Specified |

| Pricing (Basic Plans) | $150/m/u |

Not Specified |

| User Limit(Basic Plans) | 10-1000+ | 10-1000+ |

| MRP |

Yes |

Yes |

| ERP |

Yes |

Yes |

| MES |

Yes |

Yes |

| Accounting Integration |

Yes |

Yes |

| Maintenance Management |

Yes |

Yes |

| Purchase Order Management |

Yes |

Yes |

| Quality Management |

Yes |

NO |

| Shipping Management |

Yes |

Yes |

| Mobile Apps |

Yes |

NO |

Medium Grade Manufacturing Software

For medium-sized businesses, choosing better software to help them move forward can be daunting. They are already using software but want to move to the next level. This can be solved by doing extensive research and comparing various software benefits before going for one and getting it integrated. This will ensure that they streamline their process to the next level and move ahead.

You can compare the leading medium-grade manufacturing software providers here. Some of them are Oracle NetSuite, Focus MRP, and Odoo.

|

|

|

|

|---|---|---|---|

|

Oracle Netsuite |

Focus MRP |

Odoo |

|

| Free Trial |

Not Specified |

15 days | 15 days |

| Pricing (Basic Plans) | $99/u/m |

Not Specified |

$16.00/u/m |

| User Limit(Basic Plans) | 2-1000+ | 2-1000+ |

NO |

| MRP |

Yes |

Yes |

Yes |

| ERP |

Yes |

NO |

Yes |

| MES |

Yes |

Yes |

Yes |

| Account Integration |

Yes |

Yes |

Yes |

| Maintenance Management |

NO |

Yes |

NO |

| Purchase Order Management |

Yes |

NO |

Yes |

| Quality Management |

Yes |

Yes |

Yes |

| Shipping Management |

Yes |

Yes |

Yes |

| Mobile Apps |

Yes |

Yes |

NO |

Small Grade Manufacturing Software

To run manufacturing software for small businesses in India business smoothly, keeping records of the basics is important. Even a small-grade manufacturing unit requires software that will help it track the day-to-day inventory, sales, operations, etc. They should ensure that simple and easy-to-operate software provides them with the help they need to grow their business.

Some leading providers of small-grade manufacturing software are Infor CloudSuite Industrial (SyteLine), Fishbowl, and IQMS.

|

|

|

|

|---|---|---|---|

|

Infor CloudSuite |

FishBowl |

IQMS |

|

| Free Trial |

Not Specified |

14 days |

Not Specified |

| Pricing (Basic Plans) | $150/m/u | $4395/one-time |

Not Specified |

| User Limit(Basic Plans) | 10 - 999 |

NO |

NO |

| MRP |

YES |

NO |

YES |

| ERP |

YES |

YES |

YES |

| MES |

YES |

YES |

YES |

| Account Integration |

YES |

YES |

YES |

| Maintenance Management |

NO |

YES |

NO |

| Purchase Order Management |

YES |

YES |

YES |

| Quality Management |

YES |

NO |

YES |

| Shipping Management |

YES |

YES |

YES |

| Mobile Apps |

NO |

YES |

NO |

What are the Key Benefits of Manufacturing Software?

Organizations all over the globe have recognized the various benefits of cloud manufacturing process software. It is a must-have tool for manufacturing firms. Here are some useful advantages that organizations can accrue by getting manufacturing software.

-

Streamlined Inventory Management

Cloud-based Manufacturing ERP software can regulate the entire inventory system efficiently. It can manage the flow of raw materials, monitor production lines, and track the final product transfer. Manufacturing management software also ensures that there is never any shortage of any material or component. It automatically alerts once a product has reached the minimum inventory level to be replenished. This results in no production delays and boosts productivity.

-

Saves Time and Money

The manufacturing industry is highly competitive. Manufacturing process management software helps organizations escalate operational efficiency by automating all manual tasks. It propels the flow of communication between suppliers, distributors, vendors, and other stakeholders. Manufacturing accounting software facilitates data-sharing between teams and makes the supply chain flow agile and responsive. It is an intelligent platform that can reduce manual errors and save managers time from concentrating on more strategic decisions.

-

Integration With Other Systems

It is significant for software for manufacturing companies to be compatible with other systems. Most cloud-based manufacturing ERP software can be easily integrated with other platforms, accounting software, or customer relationship management systems. This leads to the smooth transfer of vast volumes of data and ensures that all company information is stored in a central unified repository.

-

Reduces Manufacturing Expenses

Manufacturing management software can help organizations increase profitability by reducing expenses to a large extent. By enhancing worker productivity, manufacturing process management software eliminates the need for a significant workforce. This reduces labor costs and overtime salary expenses. Higher accuracy rates, lower production wastages, and enhanced visibility lead to long-term savings.

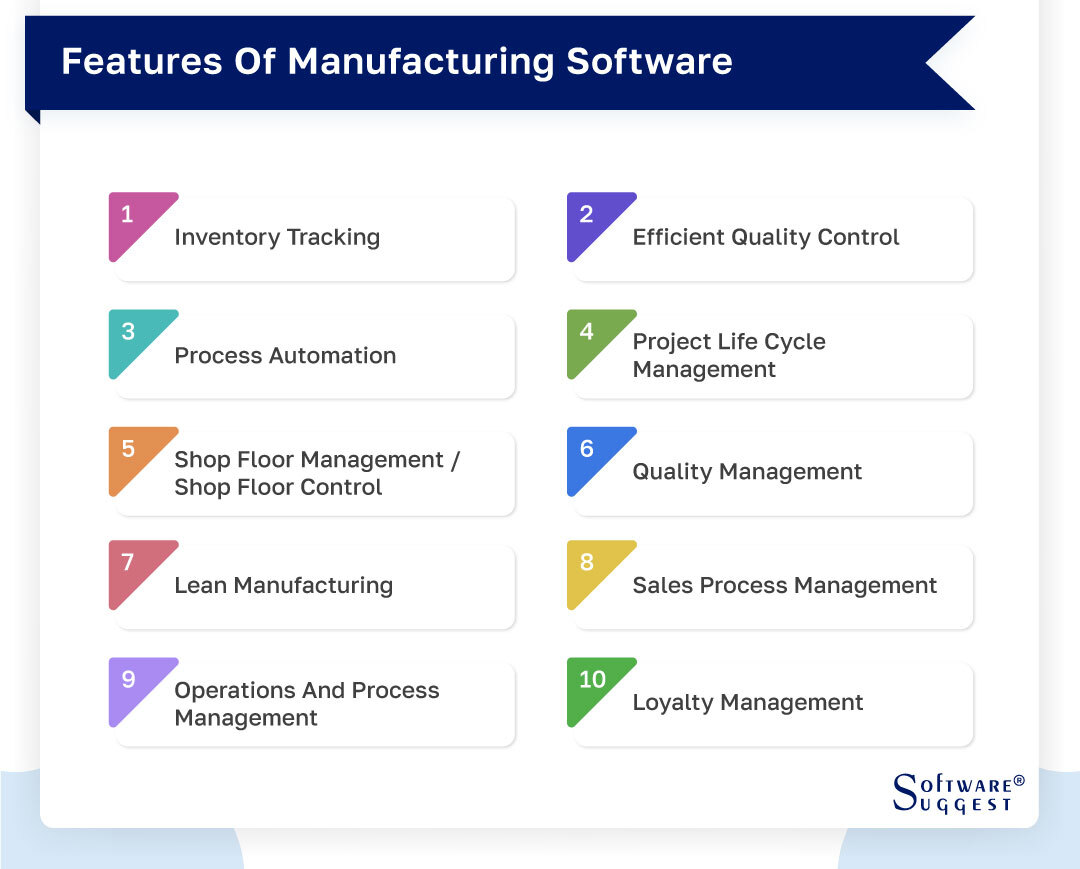

The Major Features of Manufacturing Software

Manufacturing accounting software has several distinct features. They handle all the complex processes for manufacturing companies to flourish in the business arena. Here are some vital elements to look out for in manufacturing ERP software.

-

Inventory Tracking

One of the software's most useful features for manufacturing companies is monitoring inventory at all times. Manufacturing software keeps track of raw materials, in-process goods, and finished items to ensure an uninterrupted production management software India flow. It alerts managers to re-order elements at the appropriate time and also keeps track of delivery dates. Robust manufacturing process management software automates all essential inventory functions for better task flow management.

-

Efficient Quality Control

Quality is of supreme importance in manufacturing firms. Manufacturing management software handles all critical quality functions to reduce defects in final products. This allows managers to keep the quality levels in check during every stage of the manufacturing process. The manufacturing process software facilitates automated random quality control tests to maintain desired high-quality levels.

-

Process Automation

Manufacturing accounting software results in complete process automation. The system can handle all simple mundane and administrative tasks, and it reduces dependency on manual labor. There is full integration between critical manufacturing functions such as purchase records, sales, supply chain, quality control, and material management bills. The flow of real-time information and 360-degree process visibility make software for manufacturing companies a must-have asset.

-

Project Life Cycle Management

Every manufacturing firm needs to manage new projects at different stages – from conception to production management software and distribution of the finished product. Manufacturing ERP software can help organizations monitor all these stages and ensure that projects move according to a timeline. Manufacturing management software leads to less wastage, higher quality optimization, better resource management, and time tracking. This ensures all manufacturing projects are completed on time and increases client satisfaction.

-

Shop Floor Management / Shop Floor Control

Manufacturing software offers shop floor management tools to help you manage your shop floor seamlessly. This feature enables you to manage the scheduling of resources and the workforce. It also allows you to sequence the procedures on each shop floor, allowing you to identify discrepancies and inconsistencies in shop floor communication. Shop floor management tools help manufacturing businesses enhance the positivity of their staff members by reducing the occurrences of errors in work. It also enables you to understand when you deviate from the standard procedures.

-

Quality Management

An efficient manufacturing software also has robust quality management features to ensure your products meet your customers’ requirements. Besides helping you satisfy your customers' needs, quality management tools in manufacturing software enable you to track your business activities, trace lot and serial numbers, inventory, customer return merchandise authorization, supplier return merchandise authorization, audit trails, document linking, document tracking, and much more.

-

Lean Manufacturing

It is a new concept that emphasizes reducing the wastage of resources within your manufacturing departments. At the same time, it aims at helping you maximize your productivity. Since many manufacturing companies across the globe are embracing lean manufacturing business models, the most advanced manufacturing software provides useful tools to achieve the objectives of lean manufacturing. Poor manufacturing capabilities streamline resource deployment so that you can reduce waste, besides strengthening customer loyalty. It also automates sales and service processes, product research, and development procedures. Finally, it automates the process of business analytics reporting so that you can do away with the manual steps required for financial or regulatory reporting.

-

Sales Process Management

The best manufacturing software systems come with sales process management tools to prevent you from getting entangled in complex sales processes. Sales process management tools help your sales team hit the sales target. It also lets you track deals in real time and identify qualified prospects and leads that need immediate attention. With your manufacturing software’s sales process management capabilities, you can manage customer data from a centralized location. It also helps you set up target customers, track emails, track your social media pages' performance, and more.

-

Operations and Process Management

High-performance manufacturing software consists of tools for automating your business operations and processes. Operation management tools help you plan, organize, manage, and control all manufacturing facility processes. Since finance is an essential element of operations management, the operations and process management feature ensures you utilize your funds best. It also provides actionable insights to help you with advanced planning and scheduling.

-

Loyalty management

Many manufacturing companies nowadays strive to understand the needs of their customers before developing any product. Thus, forward-thinking manufacturing companies are shifting from product-driven to customer-driven strategies. This trend drives manufacturing companies to embrace software that offers customized loyalty marketing solutions. Only by implementing a well-planned loyalty program can you comprehend your end customers' requirements and tailor your marketing strategies accordingly. A consumer loyalty program allows manufacturing companies to boost sales and generate more revenue. It also helps manufacturers communicate effectively with their customers to make the latter feel more valued. Consequently, improved customer interactions help companies create more loyal customers.

What are the Things to Consider Before Buying Manufacturing Software?

Investing in software for manufacturing companies is not a simple decision. There are many aspects that managers need to consider before getting the best manufacturing process software.

-

Scalability

Investing in manufacturing management software that can grow according to a business's requirements is vital. Most credible vendors offer scalable manufacturing accounting software. This enables small businesses to purchase additional modules to cater to diversification and growth.

-

Cost-Efficiency

The budget needs to be a significant consideration before buying manufacturing ERP software. It may seem to be a significant initial investment; however, companies need to be sure to get a quick return on investment. Manufacturing process software leads to high-scale mechanization, ultimately saving time and money for better productivity.

-

User-Friendliness

Software for manufacturing companies should have a simple and navigable interface. It should be user-friendly so all workers can quickly adapt to the system. Most manufacturing management software is very user-friendly. Hence it does not require any technical know-how or specialized knowledge for operation.

-

Integration

Manufacturing accounting software should be compatible with other existing systems in organizations. This will ensure the seamless transfer of data and boost flexibility levels. All ERP, financial, human resource, and supply chain management software suites should integrate with manufacturing software platforms for holistic functioning.

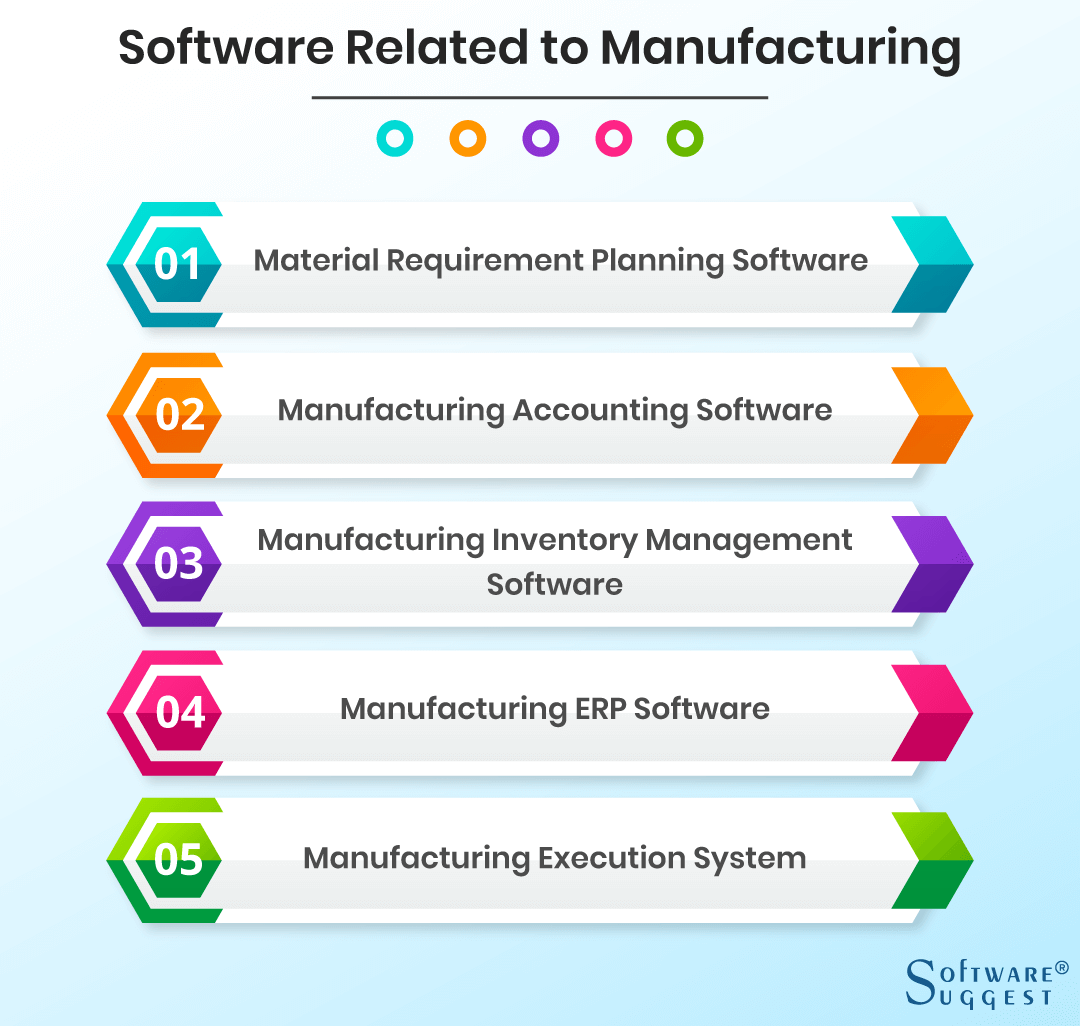

Software Related to Manufacturing

-

Material Requirement Planning Software

Manufacturing Requirement Planning Software offers shop floor management tools to help you manage your shop floor seamlessly. This feature enables you to control the scheduling of resources and the workforce. It also allows you to sequence the procedures on each shop floor and identify discrepancies and inconsistencies in shop floor communication. Shop floor management tools help manufacturing businesses enhance the positivity of their staff members by reducing the occurrences of errors in work. It also enables you to understand when you deviate from the standard procedures.

-

Manufacturing Accounting Software

Manufacturing Accounting Software has been designed to help small and large manufacturing businesses automate their accounting and bookkeeping processes. It also saves you a great deal of time, thus allowing you to focus on your business's more essential aspects.

-

Manufacturing Inventory Management Software

Manufacturing Inventory Software is emerging as an essential tool for manufacturers. The software helps you create bills related to manufacturing orders, work orders, and much more, thus, helping you work more productively.

-

Manufacturing ERP Software

Manufacturing ERP Software is a software system with a host of useful features to help you streamline manufacturing processes and complex manufacturing industry challenges to compete with global manufacturing players. The software is programmed to help you forecast sales, manage materials planning, and care for other essential aspects of your business. It simplifies your tech environment to make your manufacturing processes efficient and more transparent. Manufacturing ERP software is highly preferred by manufacturing companies as it helps them scale quickly to meet growth demands. Besides enhancing your efficiency, the software helps boost manufacturing production software and customer satisfaction. What’s more, it also lets you eliminate avoidable downtime. Some of the most impressive features offered by Manufacturing ERP software are as follows:

- Material Tracking

- Specific Manufacturing

- Integrated Data Modules

- Responsiveness

- Compliance Management

- Inventory Management

- Complex Pricing Management

- Managing Complex Pricing

- Preparing accurate bills of management

- Work-in-progress Management

- Bottlenecks Management

- Managing Returns Management

- Mobility and much more

These features go a long way toward helping you:

- Maximize the utilization of resources

- Minimize the chances of errors

- Reduce the chances of data redundancy

- Mitigate the possibilities of data duplication

- Make strategic decisions

- Reduce administrative expenses

- And enhance overall profitability

Manufacturing ERP software benefits each department of your manufacturing company. From materials planning management to making sales predictions, it helps you in every possible way to help your manufacturing business reach new success levels. The best thing about manufacturing ERP software is that it amalgamates different manufacturing processes on a centralized platform, thus, providing you with a comprehensive view of all operations.

Considering the advantages of using manufacturing ERP software, many manufacturing businesses across the world are investing in this software to compete globally. Thus, if you want to stay competitive in this dynamic business scenario, you should immediately consider investing in high-performing manufacturing ERP software. Nevertheless, ensure you invest in high-quality ERP software as purchasing an ERP system of substandard quality may prove catastrophic to your business. The wrong ERP software for your manufacturing business can also compromise security, besides destroying your workforce's morale. Thus, it is advisable to do some online research on the best manufacturing ERP software before making the final purchase decision.

-

Manufacturing Execution System

The manufacturing Execution System (MES) is a software solution for sophisticated manufacturing systems. An MES aims to ensure the seamless and systematic execution of manufacturing operations. It is used for tracking and synchronizing manufacturing processes across manufacturing plants distributed globally. The software can link all the plants in real-time to ensure optimum efficiency. MES also offers real-time data quality checks, thus, leaving no room for human error. What’s more, it also facilitates paperless manufacturing to reduce paperwork, along with paperwork mistakes. Finally, it also provides real-time feedback for timely identifying and resolving issues.

Challenges in Manufacturing Software Companies

Manufacturing software companies encounter numerous challenges in their quest to deliver efficient and innovative solutions to the industry. These challenges encompass evolving technology landscapes, market competition, and the imperative to ensure seamless integration within diverse manufacturing processes.

Let's discuss it:

-

Production planning and scheduling

Manufacturing software companies face a significant hurdle in the realm of production planning and scheduling optimization. Manufacturing operations often entail intricate processes with multiple resource interdependencies. The software must adeptly manage resource allocation, reduce downtime, and adapt to fluctuating demand to achieve production goals. Accomplishing this necessitates the application of advanced algorithms and seamless real-time data integration.

-

Quality control

The utmost priority in manufacturing lies in ensuring product quality. Challenges arise when developing software capable of vigilant and effective quality control throughout the production journey. Quality control software must seamlessly integrate with sensors and inspection tools, analyze data, and promptly trigger alerts or corrective actions when deviations from established quality standards manifest.

-

Compliance and Regulatory

Manufacturers frequently encounter a multitude of industry-specific regulations and compliance prerequisites. Manufacturing software is expected to aid in adhering to these regulations, involving tasks such as documentation, reporting, and the establishment of audit trails. Adapting to evolving regulations and safeguarding data integrity present continuous hurdles for software companies operating in this sector.

Latest Trends in Manufacturing Software

The manufacturing software landscape is continually evolving, driven by the latest trends that are shaping the industry. Staying attuned to these trends is critical for manufacturers aiming to remain competitive and efficient in today's dynamic marketplace.

-

Industry 4.0 & IoT Integration

Industry 4.0 represents the fourth industrial revolution, marked by the integration of digital technologies and the Internet of Things (IoT) into the manufacturing sector. The progression of manufacturing software is specifically aimed at facilitating this integration, enabling the smooth acquisition of real-time data from sensors and machinery. This data forms the cornerstone for predictive maintenance, process optimization, and increased automation.

-

Artificial Intelligence (AI)

AI and machine learning are ushering in a transformative era for manufacturing software. AI algorithms possess the capability to analyze extensive datasets, offering insights to predict machine failures, fine-tune production parameters, and enhance the management of supply chains. AI-driven quality control systems excel at identifying defects with greater precision, thereby elevating the overall quality of products.

-

Additive Manufacturing (3D Printing)

Manufacturing software is adapting to support additive manufacturing processes, commonly known as 3D printing. This trend involves software that can create and optimize 3D models, manage print parameters, and ensure the quality of 3D-printed parts. It offers new possibilities in design, prototyping, and even production.

-

Digital Twins

Digital twins are virtual counterparts of physical objects, procedures, or systems. In the manufacturing domain, digital twins are gaining ever greater significance. Manufacturing software has the capability to generate digital twins of production lines, enabling real-time surveillance, simulation, and enhancement.

Conclusion

In conclusion, manufacturing software has become an indispensable tool for modern businesses in the ever-evolving manufacturing landscape. From optimizing production processes to enhancing inventory management and facilitating seamless communication, these software solutions have transformed the way industries operate. As we move forward, the continuous integration of innovative technologies, such as IoT, AI, and cloud computing, will further redefine the manufacturing sector.

Manufacturers who harness the power of these software tools will not only drive efficiency but also unlock new opportunities for growth and sustainability in the years to come.

Related Research Article:

FAQs

The manufacturing process refers to the processing and combining of raw materials and ingredients into finished products like food, plastic, beverages, etc. Process manufacturing software automizes and streamlines workflows so they meet clients' needs sooner.

Production planning software helps manufacturers plan their production processes, including resource allocation, worker preparation, time management, etc.

To manage manufacturing operations, most manufacturers use ERP (enterprise resource planning) systems and sometimes other types of software such as MES (manufacturing execution systems) and QMS (quality management systems).

Manufacturing software is a type of software that helps companies plan and execute projects from start to finish by automating materials planning, manufacturing tracking, scheduling, and product life cycle management.

The cost of implementing manufacturing software can vary widely depending on several factors, including the size and complexity of the business, the specific software solution chosen, and any additional customization or integration requirements.

On average, small to mid-sized businesses can expect to invest anywhere from $10,000 to $100,000 or more for initial setup and implementation. Larger enterprises with more complex needs may face costs ranging from $100,000 to several million dollars.

By Countries

By Industries

.png)